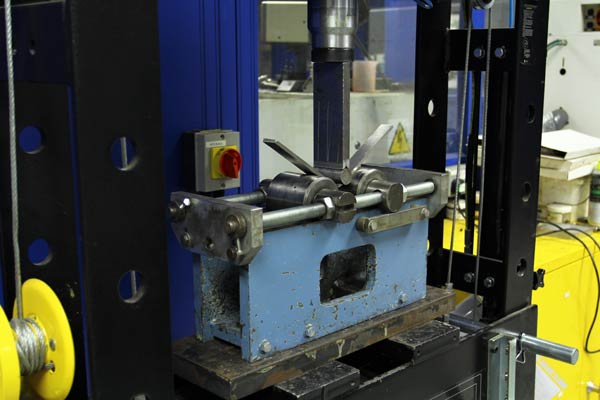

Bend Testing

Bend testing determines the ductility or the strength of a material by bending the material over a given radius.

Bend testing determines the ductility or the strength of a material by bending the material over a given radius. It is carried out under a variety of test configurations and once the sample has been bent it is then inspected for cracks on the outer surface of the bend.

The system therefore provides crucial information about a metal’s ability to undergo ‘plastic deformation’ before fracturing. Bend testing is used extensively by many industrial sectors but it is especially relevant as an integral part of the weld examinations applicable to the construction of weld procedures and associated welder qualifications, where the integrity of a welded joint needs to be fully assessed.

Tests:

Metaltest UK is equipped to provide weld integrity analysis by applying:

– 3-Point Bending

– Wrap-around Bending

– Transverse & Longitudinal weld testing

– Face, Root and Side-bend testing

– Fracture testing

Samples requiring bend tests undergo careful and precise machining prior to being placed in the relevant bending fixture to ensure accurate and reproducible results.

On receipt of samples, Metaltest UK’s machinists, technologists and metallurgists work closely together to ensure that the various processes are performed strictly to the requirements of our client whilst also ensuring that the applicable Test Standard is fully complied with.