Tensile testing is an integral component of materials science, and a fundamental part of the service we offer at Metaltest UK.

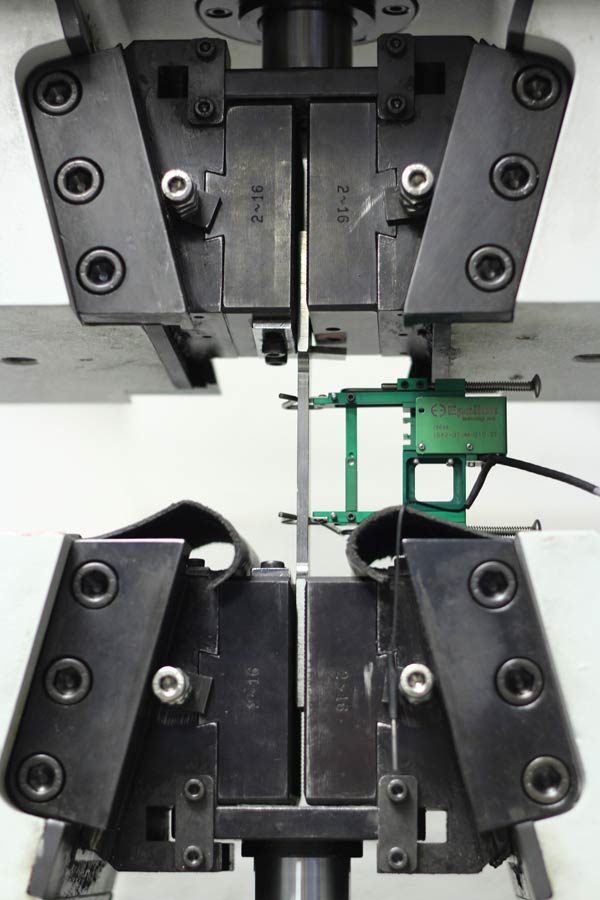

The process involves preparing length of material with a reduced mid-section, and subjecting it to a consistant load in tension until failure, with the end goal of acquiring information relating to the strength of the material being tested.

The ability to accurately measure the strength of a material or welded joint is paramount when it comes to validating material grades, helping welders achieve their codes, or qualifying weld procedures.

Working strictly to both British and ASTM Standards, samples sent to our laboratory undergo full sample preparation within our dedicated and well-equipped specialist workshop.

Tests:

Working within requirements of the relevant standards, the machined samples are then placed in our state-of-the-art tensile machine for testing where the following mechanical properties can be ascertained:

– Yield/Proof determination

– Ultimate Tensile Strength identification

– Elongation & Reduction of Area measurements

– Youngs Modulus

– Fracture face defects

– ‘Z-Test’ through-thickness properties (analysis of the quality of rolled steels)

In addition to testing raw materials, the testing of Transverse and Longitudinal mode welds is undertaken at our facility. From this we are able to ascertain the strength of the welded joint, examine weld quality (including identifying any potential defects that may be present), and also test the weld material itself (of critical importance for manufacturers of consumable electrodes).

Stress/Strain Graphs can be supplied as required, and all testing is accompanied by a comprehensive certificate of results, including a statement of conformity to specification as per customer request.