The range of metallurgical inspection services that Metaltest UK provides includes Macrographic and Micrographic Analysis (Macro/Micro-examinations).

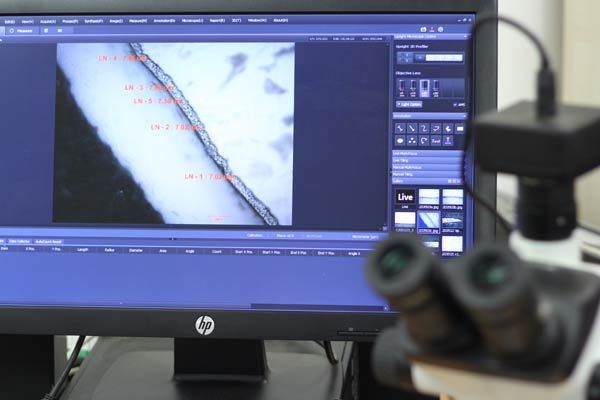

Welded samples sent to our laboratory are machined in-house before being resin mounted (subject to the sample size) and then examined by our senior metallurgist using state-of-the-art microscopes, high quality cameras and the latest software for detecting the presence of structural defects.

Analysis:

The process is particularly relevant within the following applications:

– Weld Procedure and Welder Approvals

– Weld Geometry examination

– Heat Affected Zone (HAZ) and Weld Fusion analysis

Through careful scrutinisation we have the ability to identify defects such as gas pores, cracks, lack of fusion, and geometric inconsistencies. We are also equipped to accurately measure such flaws and provide detailed reports on the extent of the imperfections throughout the inspected area.

In addition to this, our equipment has the ability to enhance any irregularities up to 500 times optical magnification for precise measurement.

The high-magnification capabilities of our microscopes are also frequently relied upon when micrographic analysis of raw materials is required.

Such circumstances are cast iron analysis (ASTM A247), failure analysis, grain directionality, forging or casting identification, steel cleanliness, or Ferrite point-counts (a test which is of particular relevance when working with Duplex stainless steels).