The Project

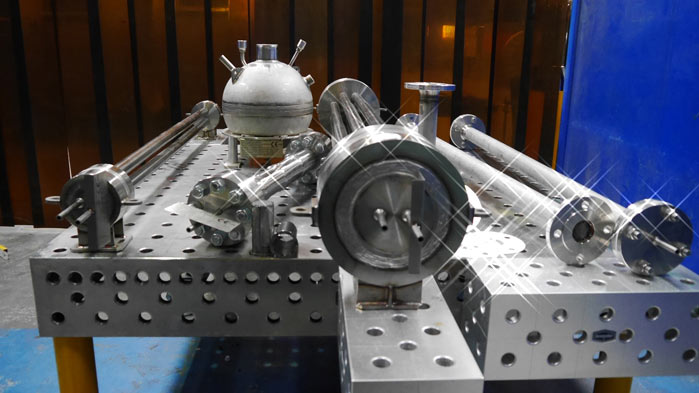

LTi were tasked with manufacturing the components involved in a much larger Government funded, ammonia green energy project. In a process known as ammonia synthesis, LTi’s components are critical to the procedure of converting hydrogen and nitrogen into ammonia, using a catalyst, which has to be performed at extremely high temperatures and pressures.

The capture of Green Ammonia is seen as crucial in helping the world to meet its twin challenges for the 21st century, namely in ensuring there is sufficient future food and energy supplies, with ammonia able to be used as a fertilizer to make land more productive and as an alternative carbon free fuel source.

LTi challenge

The original specification’s LTi received were to manufacture two receiver vessels, two heat exchangers, two vessel dryers, synthesis vessel, de-oxidisation vessel and condenser tube array component parts. These designs contained elements that presented LTi with a number of challenges. The design geometrics of these components posed real challenges, as it made them extremely difficult to test in their existing format to meet the necessary regulatory compliance. This was critical, given that these components needed to withstand immense internal pressures of over 500 bar, whilst also having an elevated working temperature.

In addition, the original materials specified had additional factors of safety built in to them, way beyond the current industry standard. The factor of safety ratio is important as it measures the load carrying capacity of a structure beyond its expected or actual loads during normal operation. Essentially, it ensures a structure is always much stronger than it needs to be for its intended load, helping to ensure safety and performance.

For LTi, the thickness of the materials used in the original spec would also have been much more expensive to manufacture, so they needed to find a way of reducing this, whilst ensuring it was still fit for purpose.

How LTi went about it

Working to EN 13445 European Pressure Vessel Standards, which sets the required minimum standards in the design, fabrication and inspection of vessels, LTi took the following steps:

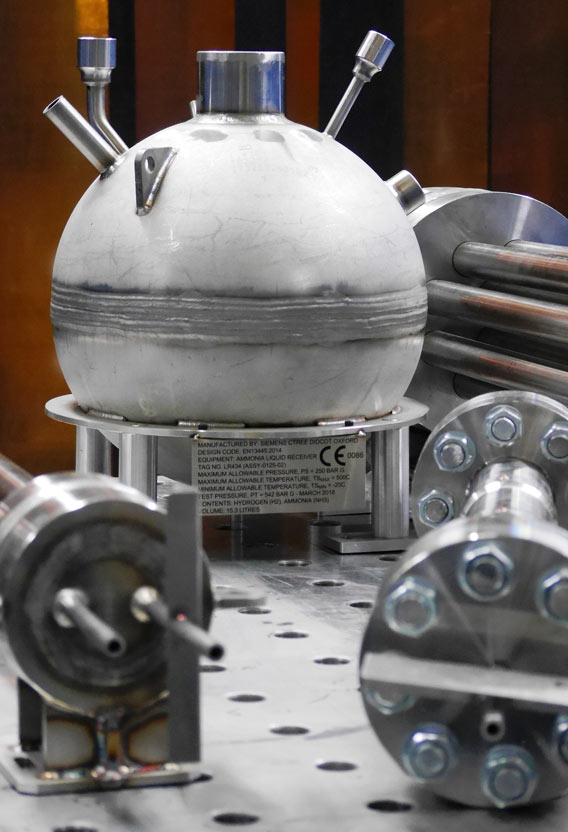

• Advised and convinced client to manufacture to a new sphere design, as a replacement to the original square based one, to eliminate any potential weaknesses and points of failure.

• Utilised our experience of pressure and vacuum vessels, to investigate how applied stresses could potentially harm the material and design, so they could ensure the necessary factor of safety was built in and ensure the quality and performance of the material was maintained. Following the reviews of this, LTi was able to fabricate the components from much thinner material than originally specified – making them lighter, much more cost effective to produce and yet still fit for purpose.

• To demonstrate regulatory compliance, components need to undergo 100% ultrasonic non-destructive testing; this is a well-established technique that utilises high frequency sound waves to locate cracks and other hidden flaws in metals, composites, and plastics. However, this was challenging for LTi, due to the original design’s geometrics. To overcome this, LTi worked closely with the British Standards Institute (BSI), conducting intermediate testing of various elements during the manufacture, to satisfy the BSI that sound engineering practices were employed throughout and ultimately ensure the regulatory compliance of these components.

• Employed optimised welding processes, using MIG (metal inert gas) rather than TIG (tungsten inert gas) welding. Essentially both welding techniques employ an electrode to generate an intense pool of heat to the parent materials being worked with, thus causing them to melt and be joined – with the weld area protected from atmospheric contamination with the use of an inert shielding gas. During the MIG welding process a metal electrode wire is also continuously fed into the weld being made, helping to hasten bonding and speed up the overall welding process. This was critical factor in LTi’s decision to employ MIG over the TIG welding technique.

What was the outcome

LTi was able to remove weight from the original design and reduce cost in the process. The customer also gained a new design that was compliant, stronger and more cost effective.